Thos Storey Orders Its First Fibre Optic Laser!

08/07/2014

Investment Made in Cutting Edge Laser Technology

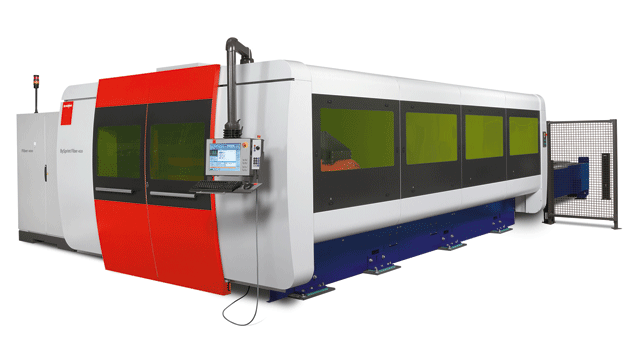

Thos. Storey are investing in the latest laser cutting technology. After four months of research and trials, an order has been placed for a Bystronic 4020 4kw BySprint Fiber Laser intended for delivery and installation late July.

Unlike our current CO2 lasers where the laser beam is created using a gas mixture, the laser beam is created by an active fibre and transmitted over a transport fibre to the machine cutting head.

With no moving parts or mirrors in the light-generating source, maintenance requirements and operation cost are radically reduced. Not only that, but as oxygen isn’t used in the cutting process you no longer get an oxidised edge to the steel meaning that paint adhesion and overall finish appearance is much better therefore allowing for greater surface protection on product.

The laser, with a bed size able to process 4m x 2m sheets, has a greatly reduced area footprint compared to the 4m x 2m CO2 laser it will replace.

The technology is far more economical to run than CO2 lasers by generating twice as much power from the same amount of current allowing much higher electrical efficiency, resulting in considerably lower running costs (a 4kW fibre machine uses one third of the power of an average 4kW CO2 machine), and running lower costs will mean that we will be able to pass on these savings to our customers by not having to increase prices in line with the ever increasing unit costs of electricity.

Summary of benefits:

· Reduced energy bills due to greater efficiency, and therefore our ability to hold prices in an ever increasing market.

· Greater reliability – no optics to adjust or align and no lamps to replace. Less downtime means a greater ability to achieve output targets.

· Minimal maintenance.

· Higher productivity - lower operational costs.

Investment is also being made into operating and nesting software with the purchase of BySoft 7 in order to optimise the By Sprint Fibre and maximise raw material utilisation. This therefore works to reduce our, and our customers’, carbon footprint.